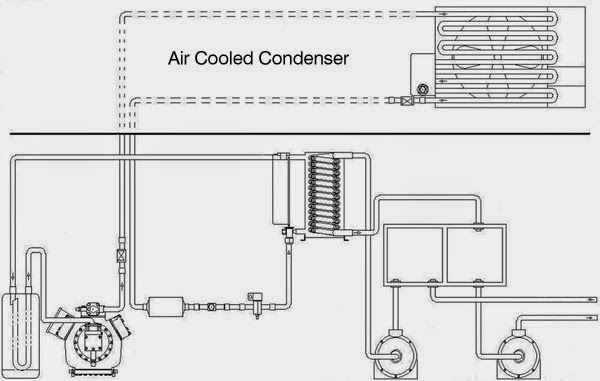

Water cooled chillers and air cooled chillers are refrigeration systems normally used to cool fluids or dehumidify air in both commercial and industrial facilities. The components of water cooled chillers and air cooled chillers are very similar. Each product contains an evaporator, condenser, compressor, and an expansion valve. The primary difference is whether air or water is used to provide the condenser cooling.

Water Cooled Vs Air Cooled

An air-cooled chiller has a condenser that is cooled by the environment air. The air-cooled chillers are preferred for small or medium installations but lately the quality improvement in their structure, allows the usage, in modular type, for large installations also. An air-cooled chiller is preferred especially in cases that there is not enough water or the water is very expensive.

The water-cooled chillers have water cooled condenser connected with cooling tower and are usually preferred for medium and large installations where there is sufficiency of water. In addition, they are also preferred in cases that is demanded constant performance of the system, independently of the ambient temperature (industrial air conditioning, air conditioning of digital systems etc), because the capacity of the water-cooled chillers are not affected by the ambient temperature fluctuations.

Flexibility

You may also note that air-cooled chillers have a much wider range in ambient operating temperatures. The wide ambient-temperature operating range allows designers' flexibility to standardize on chiller-plant designs, regardless of the data center location.

Redundancy and Effectiveness

Redundancy is essential for mission critical purpose-built data center. You should consider how long to bring the cooling system back to full load after power outages. In addition, the difficulties and cost effectiveness for installing 2N / N+1 cooling system should be carefully evaluated. Bare in mind water-cooled system should work with cooling towers and pumps.

System Maintenance and Downtime

Each chiller has basic maintenance requirements to ensure it functions at optimal levels. Though it is difficult to find a prefect cooling system with the lowest total cost of ownership (but competitive first costs), minimal operating & maintenance costs and a reduced risk of expensive downtime, we need to judged on the specific goals for every project.

Install Location

Large industrial chillers are commonly located in mechanical equipment rooms within the building close to the process in which they are cooling. Some industrial chillers may be located directly beside the process, depending on the size of the chiller and compressor. Some may even be placed completely outdoors such as rooftop of a building. Choosing which cooling system, therefore, largely depends on the building type, location, and use of the space.

About SMA

Strategic Media Asia (SMA), a critical infrastructure training and event organizer based in Hong Kong, provides an interactive environment and opportunities for members of IDC industry and engineers to exchange professional views and experience on critical infrastructure and E&M facilities.

SMA is one of the CPD Course Providers of the Chartered Institution of Building Services Engineers (CIBSE).

For details of other data center courses and seminars, please visit our website at http://www.stmedia-asia.com/trainings.html.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.